Generator conversion kit maintenance

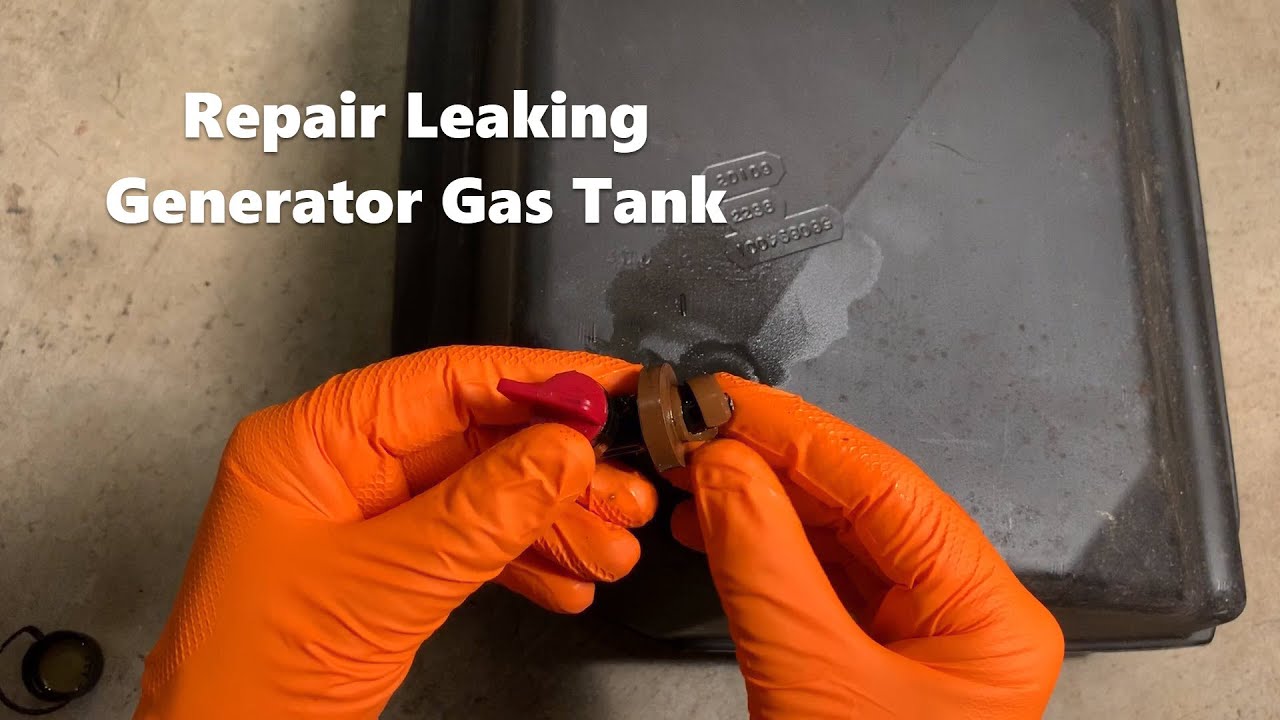

Here is the blog post regarding this video Must see this post as it is covering much more additional details about the gas kit a http 3A 2F 2Fdiycarmaint blogspot com 2F2017 2F03 2Fcng-lpg-gas-kit-maintenance-and-repair html a Here in this video I am illustrating how to maintain and adjust a gas conversion kit with a small gas engine for optimum performance avr free-energy generator AC generator or alternator is a machine used to convert mechanical energy into electrical energy The house hold alternator or generator is a combination of an engine and dynamo which produces line electric power which is 110 V or 220 V for house hold requirements The power of the produced energy depends upon the size and capacity of the generator A very common size now a days is 3KVA machine with gas engine from China manufacturing Whereas there are other varients like 5KVA and 7KVA are also in use which has car engine and a local dynamo or alternator There are diesel engine generator sets available They are big machines normally with much more power capacity The gasoline engines are sometimes run by regular gasoline and most of the time they are operated using line gas or Methane CH4 if available locally The methane or gas is cheaper for operating such engines compared to regular gasoline The methane or gas is not that strong fuel like as gasoline but due to high prices for gasoline gas is preferred fuel for such engines The gas is fed to the regular gasoline engine through gas kit The gas kit is nothing but a gas pressure and flow control device The house hold gas is regulated through company provided regulator but that is not enough for the purpose of engine to run it smoothly Further regulation is achieved by gas kit equipped with engine The gas kit has one inlet and one outlet The inlet is connected to house hold gas line and the outlet is connected to the air intake of the engine at the mouth of carburetor The gas is mixed with intake air to engine here at this point The gas kit has a mechanism that it is not providing any gas flow on the outlet till it is not sucked The gas kit is working on the negative displacement or suction principle When the engine is running it is operating like an air pump It sucks air from the intake compress it and then exhaust it The cycle repeats each time When the engine is sucking during suction stroke it produces negative pressure at intake manifold This negative pressure produces vacuum in the outlet line of the gas kit In the gas kit there is a diaphragm inside to which a lever is attached The level is further attached to a rubber stopper which is pivoted on the gas intake line of the gas kit There is a little spring tension applied on the lever which keeps the stopper in stopped position at intake at normal atmospheric pressure The spring tension is adjustable by a screw from the out side which sets the gas quantity to the engine When there is a vacuum applied on the diaphragm it attracts the lever which opens the gas intake and that gas is fed to the vacuumed line or gas kit outlet which becomes the engine fuel So during the other three stokes of the engine when it is not sucking air the gas intake is stopped by stopper as there is no vacuum in the intake of the engine This cycle continues all the time the engine runs and it is fed with required quantity of fuel Here is the image you can understand the function from Also this image is depicting the different parts Doing maintenance on a gas kit Open all 6 elan key bolts using appropriate size elan key wrench Keep them side and don't loose any bolt because they maybe fixed latter on Remove both halves of the gas kit Use a screw driver to crack open both sides if necessary Keep the one cover side Pry off the diaphragm as shown in the image below Unscrew both screws on the lever pivot By removing both screws you will be able to remove the lever from the kit Keep the spring is secure place and clean it also for future assembly Clean the rubber stopper on the control lever using a sand paper Make it smooth and clean Clean the gas kit gas intake also using sand paper Make it level and smooth Clean the pivot groves also and lubricate them with little motor oil to make the lever very much free during its operation Assemble everything back in exact reverse order you opened Then after completing the kit fix it back on the generator or engine and connect both lines Start the engine and adjust both adjustments for good engine performance Fine tune them to achieve excellent engine running and starting points Set the adjustment on such calibration Once you do it perfectly it will worth your effort by easy engine starting and excellent running Do this maintenance for the gas kit yearly or whenever required Hope this document will help those who have such kind of engines and they are about to service their gas kits

-

Select a category

There no comments on your videos ATM